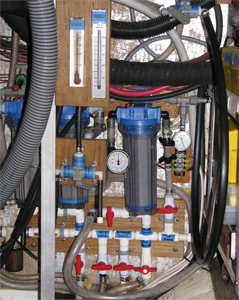

So often a technician or the boat’s crew goes to work on one of many boat systems and spends more time locating and identifying the problem than fixing it. Except for a few large production manufacturers, most boats do not come with diagrams or blueprints that show you how each system is laid-out or where the critical components are located. Additionally, different years and models along with optional accessories can result in each boat’s uniqueness compared to a similar model. This means time-consuming investigative work may be needed to get to a critical component or find how it is connected to the rest of the systems. This is not just for electrical wiring, but plumbing (water, fuel, etc.), HVACR, mechanical and even just accessibility to hidden areas.

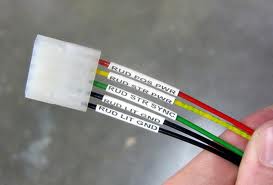

Accurate labeling can dramatically speed up the service or repair of most onboard systems. So to improve your own boat, label and identify everything. The simple act of labeling wires, pipes, access panels and switches can save so much time when it comes to identifying, operating, troubleshooting or repairing an onboard system.

Consider how many boats have an electrical panel with a switch labeled “spare,” which is NOT actually a spare but operates something important. While the daunting task of labeling or re-labeling everything on your boat may not be in the budget or time allotment, this can be completed easily little by little, and on a need-to-know basis. While you may think labeling is common sense, look under the helm or below decks of your boat and see how many wires, hoses and piping are identified and labeled.

How To Label

Store-bought Labels

If you are going to tackle labeling yourself, be sure you have an excellent quality label maker available. One example is the Brother P-touch label printers that use laminated tape technology. P-touch TZe tapes have a unique lamination, which makes the labels heat-, cold-, water-, chemical- and fade-resistant. The TZe tapes for these label makers come in a variety of sizes and colors and are readily available at big box stores, office supply stores and online too.

DIY Labels

In a pinch, blue painter’s tape and a Sharpie marker can make a quick temporary label for systems like changing batteries or removing a device with lots of wires. Though, it is best to replace the blue tape label with a professional label when possible. Writing on the wire or plumbing can sometimes work, though over time, the text often bleeds or fades, and the writing becomes a blurry illegible smear instead of an informative label.

Industrial Labels

There is a category of industrial labelers designed for commercial use and with a higher cost, but these provide much more durability and flexibility and are great for marine use. These industrial devices offer expanded printing capabilities such as materials, layout symbols and formats along with a variety of label sizes. Most industrial labelers can print the text in various fonts and orientations, allowing you to create a label that can be quickly and clearly read in almost any application. Most manufacturers offer heat shrink label material that slides over a wire, is heated to shrink and then adheres permanently for a long-lasting solution. Since industrial label material may not be as readily available, it is important to keep a variety of media materials in your toolbox.

Pre-Made Labels

If you don’t want to make your own labels, some companies offer pre-made labels individually and in sets. These include Blue Sea Systems and Paneltronics, which offer a myriad of labels designed for electrical systems on boats. If your boat has the ever-popular Carling brand rocker switches (or a similar brand or style), the removable actuator face can be custom etched with about any graphic or text to accurately describe the switch’s function. This etched cover eliminates the need for adhesive labels or engraved strips that often become outdated when modifications or upgrades change the switch location or function. One business, the Rocker Switch Pros company, has made ordering custom rocker switch covers simple and affordable.

Labeling Standards

When it comes to proper identification of a boat’s wiring, the American Boat and Yacht Council (ABYC) has a broad standard in section E-11 that reads, “Each electrical conductor that is part of the boat’s electrical system shall have a means to identify its function in the system.” There are several ways to meet the ABYC standard, such as color-coded wiring with an associated legend, labels at each end of a wire or even writing on the wire with a permanent marker. Unfortunately for other systems, ABYC has no labeling requirement, so the myriad of hoses, pumps, valves, etc. may go unlabeled.

Land-based communications systems and systems on larger boats often follow the international labeling standard ANSI/TIA-606-B. This is a voluntary standard that establishes the labeling and record-keeping standards for telecommunications and network systems in industrial, residential and healthcare facilities. It identifies what to label and offers a recommended identification system harmonized with the ISO/IEC TR14763-2-1 international identification scheme. While not required on boats, the importance and methodology can certainly be adapted for use on vessels of any size.

When it comes to marine piping, hoses, etc., there is an international standard that covers labeling. The ISO 14726:2008 standard specifies the identification for the content of piping systems for ships and marine technology. While not required on pleasure boats, this standard can be easily implemented on any boat.

When To Label

There are two easy methods to get these systems labeled. One is when an added item is installed. Whether a bilge hose, waterline or wire run, at minimum, label both ends with the pertinent info. As an example, a bilge pump hose may seem obvious and not need a label but when you have more than one on board, you could label the pump end of the hose with information about where the overboard discharge is located such as “starboard midship discharge,” and at the discharge point, you can label the hose “from starboard midship bilge pump.” This will help in your maintenance and troubleshooting tasks for years to come. The same goes for wiring. Label both ends and provide details of where that wire comes from or goes.

Secondly, be ready with your label maker when you work on an existing system, and finally find the location of that hose or wire. Label it while you are working on it and before you forget. You will need to work on it again, and many of the hoses and wires look alike a year later. Be sure your electrical panel and switches are labeled correctly. While you may know the nuances of your boat, sending a friend or crewmember to the main panel and asking them to turn on a light or pump is much easier if the panel is labeled properly.

This is also true of the spares. I don’t often find spare breakers in a boat’s electrical panel these days. They are often used for added items and usually do not get re-labeled. As an example, it is difficult for anyone else to know that the third spare breaker on the left is the backup bilge pump—especially in an emergency!

Conclusion

Labeling and identifying your boat’s systems may seem like a big task. However, the results will be gratifying and beneficial for yourself and your crew for years to come. Capt. Steve Katz is the owner of Steve’s Marine Service Inc in Ocean City, Maryland, and South Florida. He is the Chairman of the Board of The National Marine Electronics Association (NMEA) and holds ABYC Master Technician certification, NMEA NMET certification along with factory training from many manufacturers. To contact Steve, email [email protected].

About Capt. Steve Katz

Capt. Steve Katz is the owner of Steve’s Marine Service Inc in Ocean City, Maryland, and South Florida. He is the Chairman of the Board of The National Marine Electronics Association (NMEA) and holds ABYC Master Technician certification, NMEA NMET certification along with factory training from many manufacturers. To contact Steve, email [email protected].