Table of Contents

The Dawn of Marine Diesel Engines

Marine diesel engines (or compression ignition engines as defined by the EPA) have been the workhorses of marine propulsion since their inception. It was early in the 20th century when the first four-stroke diesel engine was installed in a boat, and soon afterwards, two-stroke diesels evolved as the powerplant of choice. Now they have been replaced with the modern, computer-controlled four-stroke diesel engine.

Maritime Emission Standards

Shortly before the turn of this century, the United States Environmental Protection Agency (EPA) began regulating pleasure boat marine engines commonly used in today’s sportfish boats and many other vessels. Since 2008, the EPA has been phasing-in increasingly stringent emissions requirements in steps, or “Tiers.” There are lots of compliance dates, emission standards and categories to keep track of. Here are some details: the EPA, for the purpose of emission regulations, have classified marine engines into three categories based on displacement (swept volume) per cylinder. Each of the categories represents a different engine technology.

Categories 1 and 2 are further divided into subcategories, depending on displacement and net power output. International emission regulations set forth by the International Maritime Organization (IMO) began in 1997 and first took effect in 2005. Often referred to as MARPOL Annex VI regulations, these overlap with our US EPA standards. The IMO standards are important since typical marine diesel engines are used and sold worldwide and manufacturers want their engines to meet all standards, not just those here in the USA.

Challenges and Solutions in Compliance

Fortunately, back in 2021, the USCG delayed enforcement of the IMO Tier 3 requirement for vessels over 90 feet. At the time and even today, the ability to provide an IMO tier 3 engine requires the use of SCR (Selective Catalyst Reduction) systems. Primarily requiring diesel exhaust fluid (urea) treatment, this system will add bulk and weight to an engine room and could become a safety issue. This emission standard compliance is one of the reasons that Viking yachts created the new 90-foot sportfish (that doesn’t fall into the compliance length for IMO tier 3) to take the place of the larger 92-foot model.

Considerations for Boat Owners

The good news is that if you are buying a new or used boat, there shouldn’t be much concern that your engines are or are not compliant with the then applicable EPA emission standards — at least for now. The concern for sportfish boat owners is when it comes time to repair, rebuild or replace an engine. An event like this could trigger a compliance issue. While the EPA will probably not show up at your boat to test the engine emissions, the engine manufacturers, re-builders and associated companies are required to assure their business are offering engines that meet current EPA Tier emission standards.

Advancements in Fuel Efficiency and Power Output

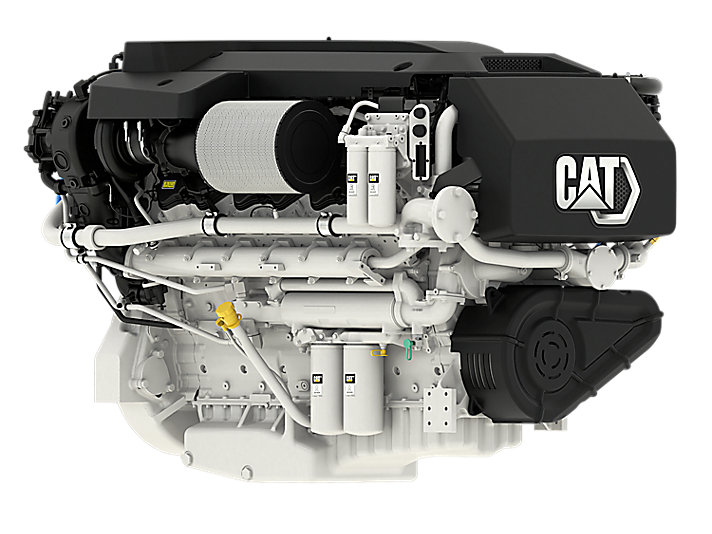

It turns out the stricter emissions standards have a positive byproduct. Reduced emissions have primarily been obtained by additional computer controls that allow for a more complete fuel burn, which increased the power output and reduced fuel consumption at the same time. For example, the new Caterpillar C32B Diesel Engine is a 12-cylinder, triple turbo marine engine that is Tier 3 and IMO compliant, and is more powerful and 25 percent quieter at trolling speeds than its predecessor, the 12-cylinder C32 ACERT engine. This engine uses a unique “split shot” fuel injection technique, more advanced than the typical modern common rail engine. The individually pressurized injectors send fuel to each cylinder in two doses, one small “pilot” burst followed by a second or “main” larger burst of fuel. Caterpillar indicates that breaking up the combustion process dampens combustion noise and adds to efficiency. The top-of-the-line C32B engine produces 2400 bhp, making it the most powerful and cleanest burning 12-cylinder marine engine manufactured by Caterpillar.

Leading Diesel Engine Innovations

MTU, (Motoren-und Turbinen-Union) the well-known German Diesel Engine manufacturer founded by the Maybach family, has been in the diesel engine business since the early 1900s. The MTU company is now a wholly owned subsidiary of Rolls-Royce Holdings. Eight years ago, MTU debuted the IMO Tier II and EPA Tier 3 certified 2000 M96 engine series for marine use. Over the years MTU has offered the M96 engines in 10-, 12- and 16-cylinder versions. The most powerful is the 16V 2000M96L Diesel Engine that produces 2600 bhp. MTU’s smaller engine, the 12-cylinder 12V 2000M96X Diesel Engine, produces 1974 bhp, a worthy competitor in that class.

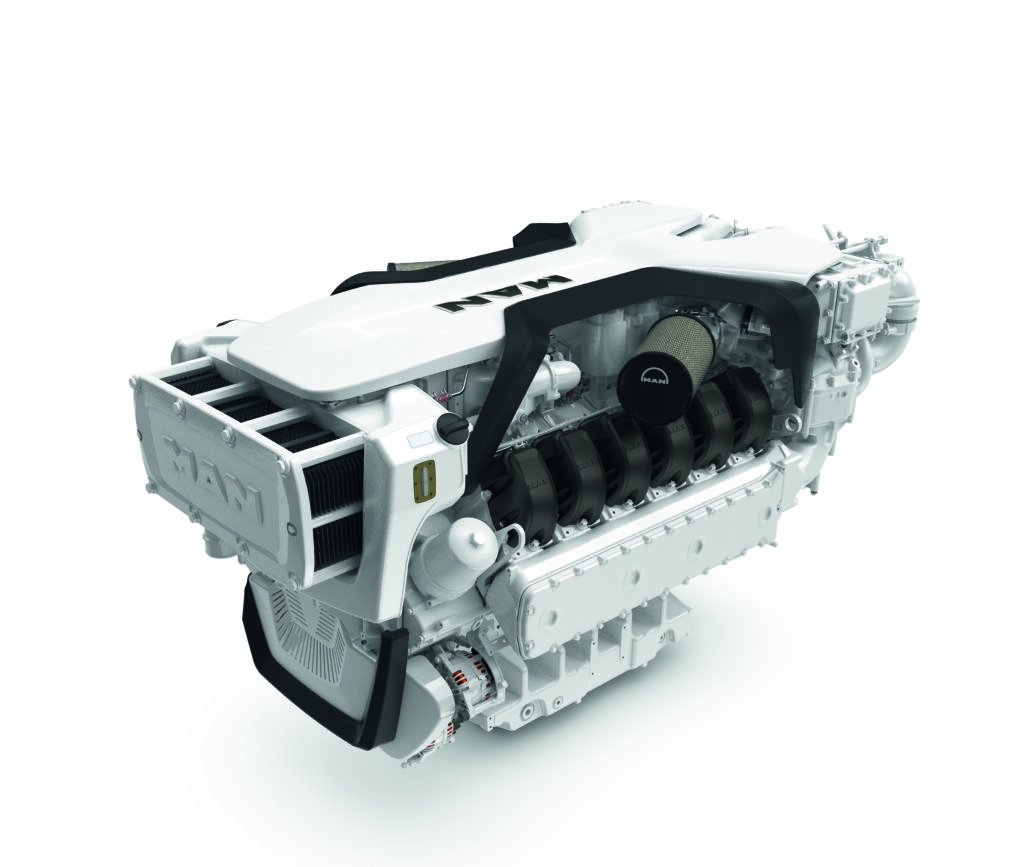

Not to be outdone, MAN, the German Diesel Engine conglomerate, offers the highest power density marine engine on the market, the MAN V12-2000, with 2000 bhp from 24 liters displacement. This is not the same hardware as previous engines, it has an improved injection system, new turbochargers, new cylinder heads and an adjusted cooling system. This engine also includes a new reinforced crankcase to complete the upgrade. It also meets EPA Tier 3 standards for recreational vessels and IMO tier 2 and therefore can be operated in popular global areas. This latest engine uses MAN’s EDC17 electronic injection system to assure efficient combustion. This precise fuel system helps promote a quieter-running engine with less vibration and lower fuel consumption than previous models. This electronic system contributes to meeting the EPA and IMO emission requirements. These modern diesel engines rely on myriad computers, sensors and other control systems, most of which are beyond our control, but we can control the air fuel, oil, and cooling systems. Of these, the most important is the fuel system.

The Importance of Fuel and Oil Management

Before we talk about fuel filters, let’s talk about the High-Pressure Common Rail (HPCR) marine engines. Some of these Diesel Engine have final fuel pressures as high as 30,000 psi. “The higher pressure of common rail fuel injection allows the engine to atomize the fuel and air mixture better so more of the fuel burns in the cylinder, reducing particulate emissions,” said Jeff Sherman, marine sales manager for MTU. These engines need to have very clean fuel, and most engine manufacturers require the fuel supply to meet ISO 4406 standards for a particle count rating of 18/16/13. This coding system (i.e., 18, 16, 13) corresponds to the numbers of particles of a size greater than four, six and 14 microns per milliliter of fuel, respectively. The number 18 expresses that there will be a maximum of 2,500 particles equal to or larger than four microns; the number 16, that there will be a maximum of 640 particles equal to or larger than six microns; and the number 13, that there will be a maximum of 80 particles equal to or larger than 14 microns in a milliliter of fuel. The critical maximum particle sizes for modern injection systems are between four to six microns. These particles are smaller than what we can detect by eye.

The cleanliness of fuel is not just for keeping the system from clogging, that’s a given these days, but to prevent abrasive damage and the subsequent accelerated wear that can quickly occur to the injectors and other system components that could result in degraded performance, increased emissions, or component failures. The best way to assure you have clean fuel is through multistage filtration where the fuel from the storage tanks flow through progressively finer filters before it gets to the finest (smallest micron) engine-mounted filter. There are some folks who don’t like changing the engine-mounted fuel filters (secondary filters), understandably so. They are expensive, time consuming to change, and can easily induce air into the fuel system during a change. This causes some operators to install a finer (smaller micron) filter in the primary filter location in the hopes they can prolong the life of the secondary filter.

This is not acceptable in today’s engines and not recommended by the engine manufacturers. The popular Racor Turbine Series primary fuel filter is designed to remove water and particulates of larger size (30- or 10-micron at a given efficiency ratings) and the engine-mounted filter is designed to remove particulate down to about five microns or smaller (depending on the manufacturer). These multiple filters work in unison, sharing the filtering task, resulting in the cleanest fuel for the engine. MTU has recently approved the Racor FBO series filter for use as a primary filter on their 2000 series engines.

When changing secondary filters, they should be installed dry, not filled with fuel from a jug before installation. Once installed on the engine, the fuel priming system should be used to fill the new secondary filter and purge air out of the fuel filter and related components. The reason for this is that by pouring fuel from a jug or container directly into the secondary filter you bypass the primary filter and at the same time allowing unfiltered fuel to go directly into the engine’s fuel injection pump.

While not as popular with sportfishing boats as they are with yachts, there are on-board fuel quality test kits that allow a crew member to test the fuel supply before adding fuel to the boat’s tanks. This may be more critical when traveling to distant foreign ports than your local marina fuel dock. These specialized test kits can identify water and microbiological contamination (algae) quickly. There are more complex test kits available, though any test is a good idea where the fuel supply may be questionable.

Looking Forward: The Future of Marine Diesel Engines

When it comes to lubricating engine oils, it is always a good idea to only use the engine manufacturer’s recommend products, or products that exactly meet their specifications. Today’s oils serve many purposes: lubricating the moving parts, plus absorbing, and removing (in the filter), combustion byproducts. These oils are formulated to work with the recommended fuel supply and are a critical part of keeping your engine operating in top condition. Periodic oil sampling is a great idea to keep an eye on the health of your oil and the engine in general. Some engine warranties require period oil samples sent to the manufacturer for review. There are also independent oil analysis laboratories that can analyze and explain the results of their laboratory analysis. Blackstone laboratory is a popular independent laboratory many boaters use.

Today’s marine diesel engines offer advancements in almost every area, and the primary driver for these innovative advancements has been the looming worldwide emission standards. It’s not often we can thank regulators for helping create better products, but let’s focus our enthusiasm back on the engine manufacturers and their engineers propelling us into the future. Thanks for the horsepower.

Don’t Forget to Check Out Our Sportfishing Job Board! Did You Know? It’s the perfect platform for seeking skilled captains and mates. Whether you’re on the hunt for your dream team or looking to join one, your next big adventure begins here. Explore the opportunities now! Click Here